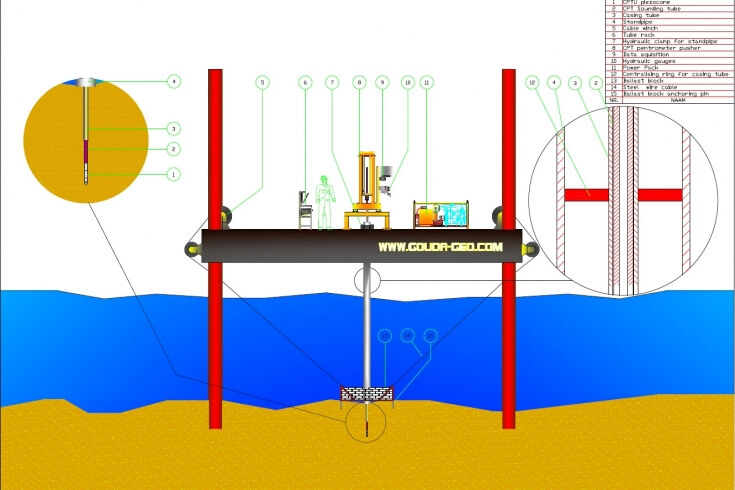

When working over water, a “standpipe” is to be used at all times. This pipe shall act as the major casing through which all other tubes will run, such as the CPT casing, the CPT sounding tubes and the possible drill-string. The design of the standpipe is crucial; it determines the success or failure of a nearshore CPT project.

Over the years we have learned that an awful lot of pushing force can be lost due to friction on the string of sounding tubes. Staggering losses of pushing force of 90% and more have been observed. This was all due to the insufficient design of the standpipe.

When the free play between the exterior of the CPT sounding tubes and the inside of the supporting casing is too large, the string of sounding tubes is allowed too much space and tends to buckle. This will result extremely high forces on the inside of the supporting casing and lead to tremendous loss of pushing force.

Other causes that can lead to loss of pushing force are the inflow of material at the shoe (which creates a plug) and the fact that the standpipe is not placed perfectly vertical.

The standpipe has to be lowered by means of a crane or alike and fixed into the seabed in such a manner that the current has no influence on the standpipe. This can be achieved by pushing the shoe of the standpipe into the seabed or by using a ballast block at the bottom end of the standpipe.

In general the standpipe sinks into the seabed as a result of its own weight. This has to be verified by comparing the length of the standpipe with the water depth and the elevation of the deck above water level.

If the standpipe is not firmly in place, one risks that the standpipe will be displaced by tidal influences or waves, making it impossible to continue the CPT test. A secure fixing of the standpipe to the deck of the working platform is also very important. This can be done by means of hydraulic holding clamp, that prevents the standpipe of sliding further (e.g. by its own weight) into the seabed.

The best moment to place the standpipe is at neap tide when the influence of the tide is minimum. The standpipe is for obvious reasons be placed as vertical as possible.

It is recommended to equip the standpipe with 2 inclinometer sensors to monitor the verticality of the standpipe. The shoe of the standpipe is to be equipped with 4 lifting eyes (in NESW orientation), which make it possible to adjust the verticality of the standpipe using 4 simple winches on the deck.

Certainly near the seabed it is recommended to opt for an open design of the standpipe so that material can flow freely in and out of the standpipe and the risk of clogging is avoided. This makes the standpipe also less susceptible for the underwater current.

A lifting ring with lifting eye(s) is required to lift the standpipe in and out of the moon pool.

It is advisable to design the ballast block such, that it can be made heavier by adding more ballast in case of heavy current. Pins are recommended at the bottom to avoid lateral movement over the seabed (the pins will sink more easily into the seabed).

The standpipe is to be designed such that it can be used for both CPT testing and over-drilling.

The standpipe should compose of elements of different length making it feasible to build a standpipe having the right length since water depths might vary from spot to spot.

Always opt (if possible) for a flange connection. It is much easier to connect two pipes that way and it results in a more ridged standpipe. Use flush connections only in case of a small diameter moon pool.

Standard CPT casing tubes are 1 meter long and have an inner diameter (ID) of 39 mm and an outer diameter (OD) of 55 mm. As can be seen, the tolerance between the OD of the CPT sounding tubes (36 mm) and the ID of the casing tubes (39 mm) is small, which is essential in order to provide sufficient lateral support of the CPT sounding tubes and prevent buckling.

The OD and ID of the standpipe are not defined. They depend on water depth, local conditions (flow, waves) and availability. Spacers are normally welded on the CPT casing tubes at 2 m intervals, again with a small tolerance between the spacer OD and the ID of the standpipe. The maximum OD of the standpipe is limited by the ID of the moon pool and the on-board lifting capacity (weight).

For nearshore CPT testing we always advise to use a 15 cm² (piezo-) cone in order to anticipate possible high load on the cone. Since the 44 mm CPT sounding tubes are about 2.2 times stronger, we recommend these as well. To overcome the friction on the string of CPT sounding tubes inside the standpipe, we recommend to use a 350 kN CPT penetrometer pusher instead of a 200 kN rig.

If a client wishes, the Gouda-Geo design team can make the design of a standpipe for your project(s) based on water depth, current, seabed material, seabed “landscape”, type of jack-up barge, on-board lifting capacity, moon pool diameter, type of CPT test, etc.

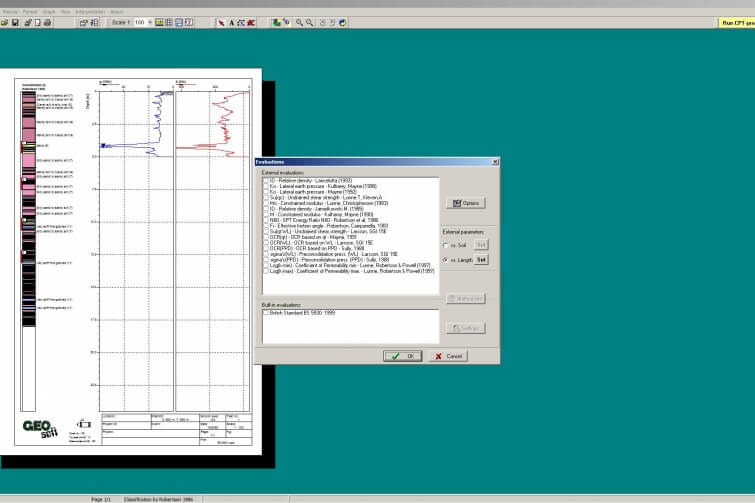

The 350 kN stand-alone CPT penetrometer set for nearshore testing is an economical rig with full CPT testing capabilities. It is because of its design and possible extra’s very suitable for cone penetration testing in relatively shallow waters, i.e. up to approx. 25 meter. The CPT set is suitable for both electrical and mechanical CPT testing, but in daily

practice only used for electrical CPT.

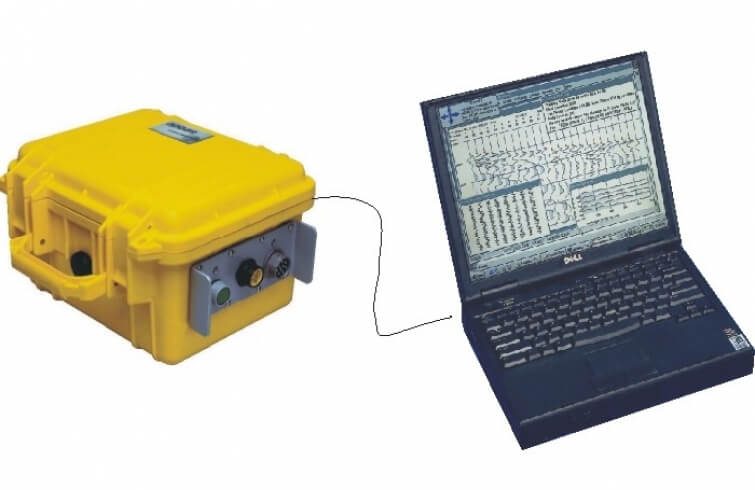

The CPT penetrometer set comprises a 350 kN 2-cylinder CPT penetrometer pusher, a diesel-hydraulic or an electric-hydraulic power-pack with load-sensing pump, manually operated valves, mounting frame, stainless-steel housing for datalogger and computer, etc.

A hydraulic CPT penetrometer pusher with a pushing capacity of 350 kN, comprising 2 vertical hydraulic cylinders, simultaneously operated with a stroke of 1350 mm. A thrust block connects the two cylinders and is capable of driving and pulling the CPT sounding tubes and casing tubes into and out of the ground.

A hydraulic control unit, mounted on a console near the CPT penetrometer pusher, allows the operator to control all functions. The unit comes complete with a guiding tubes, to be applied between the penetrometer and ground level.

- Max. pushing force: 350 kN

- Max. pulling force: 450 kN

- Unloaded speed up: 105 mm/sec

- Unloaded speed down: 145 mm/sec

- CPT testing speed: 20 mm/sec

- Weight: Approx. 740 kg